Automatic tube Filling And Sealing Machine Pharmaceutical Granulation Equipments For Aluminum Tube

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HUALIAN YIMIN |

| Certification: | OQ,IQ,DQ |

| Model Number: | GF-400F |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SETS |

|---|---|

| Price: | USD 35000.00 /SET |

| Packaging Details: | standard wooden case |

| Delivery Time: | 30 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 400 sets/month |

|

Detail Information |

|||

| Modle: | GF-400F | Hose Material: | Plastic Pipe, Composite Pipe |

|---|---|---|---|

| The Length Of The Hose: | φ13-φ60(mm) | Work Pressure: | ≤±1% |

| Motor Power: | 1800-3600 Support / Hour | Overall Dimensions: | 2620×1020×1980mm(L×W×H) |

| The Host Weight: | 1100kg | ||

| Highlight: | high speed mixing granulator,vibrating fluid bed dryer |

||

Product Description

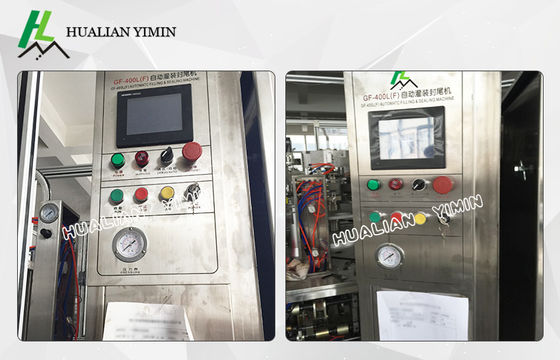

GF-400F tube filling and sealing machine

product description:

The product has the characteristics of reasonable structure, complete functions, convenient operation, accurate loading, stable operation and low noise.

The PLC programmable controller is used to program the whole machine, from liquid to high viscosity fluid material (paste) for filling and sealing to code number (including production date) and other processes. It is an ideal equipment for filling and sealing aluminum tubes, plastic tubes and composite tubes in cosmetics, pharmaceuticals, food, adhesives and other industries, and meets GMP requirements.![]()

![]()

![]()

![]()

Product features:

1, high grade liquid crystal display programming controller and button operation video, a comprehensive grasp of the equipment stepless speed regulation, parameter Settings, output count design, pressure indicator, fault display and other operating conditions, make the operation simple and user-friendly.

2. This machine adopts 12-station structure design, which can automatically complete the whole process of tube supply, calibration, inert gas filling (optional), filling, tail sealing, coding and finished product export.

3. The high-precision calibration system reduces the error range of the color standard of the pipe body.

4. The adjustment position is external and the position scale is displayed by digital display, which makes the adjustment quick and accurate (suitable for production of multiple specifications and varieties).

5. Machine, light, electricity and gas integration, realizing no tube and no filling, no supply tube in place, low pressure, automatic display (alarm); Open the protective door can automatically stop the machine and other automatic functions.

6. The same machine can be equipped with different molds to fill and seal different specifications of metal pipes, plastic pipes and composite pipes.

7. Water circulation insulation sandwich material barrel and automatic stirring system can be selected to make the material more even and more ideal.![]()

![]()

![]()

![]()

![]()

Technical Parameters:

| F-type technical parameters | |

| Hose material | Plastic pipe, composite pipe |

| Hose diameter | φ13-φ60(mm) |

| Hose length | 50-250 (mm) |

| Filling capacity | 3-400ml / support |

| Filling accuracy | ≤±1% |

| Production capacity | 1800-3600 support / hour |

| working pressure | 0.4-0.6 Mpa |

| Motor Power | 2Kw(380V/220V 50HZ) |

| Dimensions | 2620×1020×1980mm(L×W×H) |

| Host weight | 1100kg |

Installation size diagram:

![]()

Equipment detail map:![]()

![]()

![]()

![]()

![]()