GMP Double Cone Rotary Vacuum Dryer For Drying Food Powder And Medicine

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HUALIAN PHARMD |

| Certification: | ISO,GMP |

| Model Number: | FD-SZG |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard wooden case |

| Delivery Time: | 50 DAYS |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 Set/Sets per Mont |

|

Detail Information |

|||

| Model No: | FD-SZG | Speed(rpm): | 6 |

|---|---|---|---|

| Power(Kw): | 1.1 | Tolal Weight(Kg): | 550 |

| Product Name: | Pharmaceutical Granulation Equipments | Brand: | HUALIAN PHARMD |

| Highlight: | high speed mixing granulator,vibrating fluid bed dryer |

||

Product Description

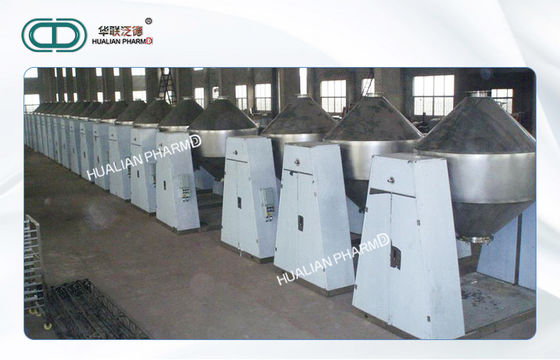

Factory price double cone rotary vacuum dryer for drying food powder and medicine

Description:

As a professional factory in drying industry, we supply hundred sets to thecustomers every year. As for heat medium, it may be thermal oil or steam or hotwater. For drying the adhesive raw material, we have designed specially a stirringplate buffer for you.

![]()

![]()

Principle:

● Heat source (for example, low pressure steam or thermal conduct oil) passthrough the sealed jacket. The heat will be transmitted to raw material to bedried through inner shell;

● Under driving of power, the tank is rotated slowly and the raw material inside itis mixed continuously. The purpose of reinforced drying can be realized;

● The raw material exists is under vacuum. The drop of steam pressure makesthe moisture (solvent) at the surface of raw material become saturation and willevaporate. The solvent will be discharged through vacuum pump an recoveredin time. The inner moisture (solvent) of raw material will infiltrate, evaporate anddischarge continuously. The three processes are carried out unceasingly andthe purpose of drying can be realized within a short time.

![]()

![]()

Technical characters:

1. When oil is used to heat, use automatic constant temperature control. It can beused for drying biology products and mine. Its temperature of operation can beadjusted form 20-160 "C .

2. Compared to ordinal dryer, its heat efficiency will be 2 times higher,The heat is indirect. So the raw material can not be polluted. It is in conformitywith the requirement of GMP.

3. It is easy in washing and maintenance.

![]()

![]()

Main Technical Parameter:

|

Itme |

||||||||||||

| Name | Unit | 100 | 200 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

| Total volume | L | 100 | 200 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

| Working volume | L | 50 | 100 | 175 | 250 | 375 | 500 | 750 | 1000 | 1500 | 2000 | 2500 |

| Heating area | ㎡ | 1.16 | 1.5 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 10.2 | 12.1 | 14.1 |

| Speed | rpm | 6 | 5 | 4 | 4 | 4 | ||||||

| Power | Kw | 0.75 | 1.1 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 |

| Rotating height | mm | 1810 | 1910 | 2090 | 2195 | 2500 | 2665 | 2915 | 3055 | 3530 | 3800 | 4180 |

| Total weight | Kg | 550 | 700 | 900 | 1100 | 1200 | 1300 | 1500 | 2000 | 3000 | 4000 | 5000 |

| Design pressure inside the tank | Mpa | -0.09~0.096 | ||||||||||

| Design pressure of jacket | Mpa | ≤0.3 | ||||||||||

Schematic of installation:

![]()