high speed film Shrink Sleeve Seaming Machine , Glue Sealing Machine Mold Less Type

Product Details:

| Place of Origin: | ZHEJIANG |

| Brand Name: | HUALIAN EYSET |

| Certification: | CE |

| Model Number: | YS-ZHA 300 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD 22000- 29000/SET |

| Packaging Details: | standard wooden case |

| Delivery Time: | 35 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200sets/month |

|

Detail Information |

|||

| Model: | YS-ZHA 300 | Width Of Unwinding: | 620mm |

|---|---|---|---|

| Diameter Of Unwinding: | Ø600mm | Diameter Of Rewinding: | Ø700mm |

| Min. Sealing Size (mold-less): | 80mm | Min. Sealing Size (plates): | 30mm |

| Max Working Speed: | 400m/min | Dimension: | 2500x1300x1600mm |

| Highlight: | sleeve seaming machine,screw air compressor |

||

Product Description

ZHA-300 PVC Sleeve seaming Machine/ GlueSealing Machine (Mold-less type)

CHARACTERISTIC:

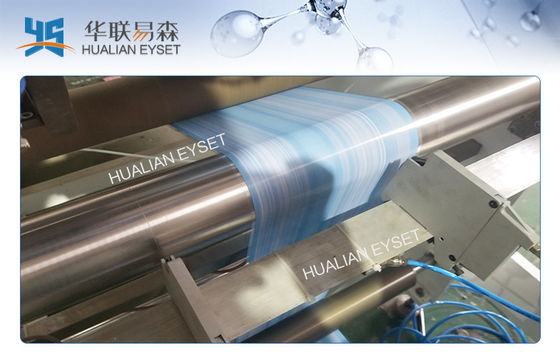

Model ZHA-300 High Speed Sleeve seaming machine(mold-less type) is specially used in folding and glue sealing film material (such as PET, PVC. etc) into sleeve type for bottole labels.

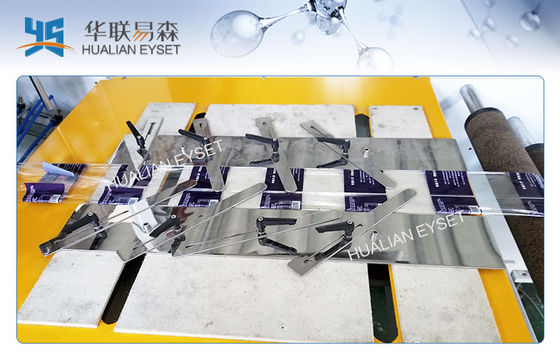

Most advantage of this machine: Mold-less plates, It means when you change sealing sizes, you only move the distance between 2 plates, without making new plates.

![]()

1. Main Technical Parameter:

| Model | 300mm |

| Width of Unwinding | 620mm |

| Diameter of Unwinding | 600mm |

| Diameter of Rewinding | 700mm |

| Min. Sealing size | 80mm |

| Max. Sealing size | 300mm |

| Max Working Speed | 300m/min |

| Voltage of Whole Machine |

220V/50HZ/1phase (other voltage, please inform) |

| Dimension of Whole Machine | 2200x1300x1500mm |

Configurations:

1)Stable and heavy-duty frame for high speed operation of 300n/min.

2) Adjustable forming plates creates efficient operation. (Changing sizes without change plates)

3) Auto solvent feeding control.

4) Auto tension control for unwind/rewind unit to maintain the optimun tension.

5) Good brand EPC device, precision 0.1mm.

6) Accurate and stable product width.

7) Cantilevered rewind/unwind shaft for fast roll changeover.

8) PLC with color touch screen control system.

9) Needle type glue method, work with glue pump and PLC.

10) Rewind oscillation control to produce high quality rolls.

11) Static eliminator is adopted before rewinder.

12) Whole machine with 3 pcs of servo motors for traction, rewinder, oscillation, and 1pc of magnetic brake for unwinder.

Optional:

1) Perforation device

2) LED light for checking gluing quality

3) Hot melt glue device

4) Double eyes sensor osscillation

![]()