Pharmaceutical Food High Speed Tablet Press machine for medicine two colors tables 1400×1500×1900 Overall Size

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HUALIAN YIMIN |

| Certification: | CE,ISO |

| Model Number: | GZPK-620 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | negotiable |

| Packaging Details: | standard export wooden case |

| Delivery Time: | 60 days |

| Payment Terms: | L/C, T/T, D/A |

| Supply Ability: | 50 sets/month |

|

Detail Information |

|||

| Product Model: | GZPK620-65 | Maximum Depth Of Filling(mm): | 16 |

|---|---|---|---|

| Maximum Prepress Force(kn): | 16 | Wafer Diameter Range(mm): | 13 |

| Total Energy(kw): | 11 | Overall Size Of Equipment: | 1400×1500×1900 |

| Equipment Net Weight(kg): | 3300 | ||

| Highlight: | rotary tablet press,powder compacting press machine |

||

Product Description

GZPK620-65 automatic high-speed tablet press

GZPK620 discharge high-speed rotary tablet press, the machine adopts double forced feeding and double tablet structure design, and the process of two times filling, metering, preloading, main pressure and tablet production can be completed in one plate, with the maximum output up to 580,000 pieces/hour. Stable equipment performance, smooth operation of the machine, low noise, low noise. Replace a set of guide rail, double pressure double layer piece.

![]()

Main features

1. Comply with GMP specification requirements, compact structure, reliable performance, simple operation.

2. Man-machine interface touch screen software operation control, convenient operation, with self-diagnosis function of fault point.

3. The touch screen hydraulic control main pressure wheel pressure and prepressure wheel pressure plate weight automatic detection function, appear scrap automatic identification function.

4. Up and down overcharging protection, electronic control system protection, host overload shutdown protection, forced feeding motor overload protection, air source pressure is too low protection, system fault automatic alarm protection.

5. Automatic lubrication system.

6. Production information can be displayed, printed and stored.

![]()

Main technical parameters

|

Product model |

GZPK620-65 |

| Maximum capacity(pc/h) | 790000 |

| Maximum depth of filling(mm) | 16 |

| Maximum principal pressure(kn) | 100 |

| Maximum prepress force(kn) | 16 |

| Tablet thickness range(mm) | 1-8 |

| Wafer diameter range(mm) | 13 |

| Long edge range of profiled piece(mm) | <14mm |

| Piece of heavy differences | ±3% |

| Working noise | ≤80dB |

| Total energy(kw) | 11 |

| Overall size of equipment | 1400×1500×1900 |

| Equipment net weight(kg) | 3300 |

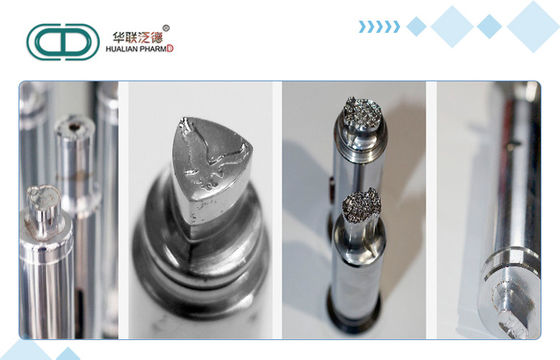

Working steps

1. The punch part of the down-flush (its working position is upward) extends into the middle die hole from the lower end of the middle die hole and seals the bottom of the middle die hole;

2. Fill the middle mold hole with drug by feeder;

3. The punch part (its working position is down) of the upper end of the middle die hole falls into the middle die hole and travels down for a certain distance to press the powder into tablets;

4. Upward flush lifting hole. Push the tablet out of the middle die hole and complete the first pressing process;

5. Descend to the original position and prepare for the next filling.

![]()

![]()

Control technology for the connection of the whole production line of the tablet press: one tablet press can be connected to a production line, which is the function of the tablet press in Germany and Britain. It has a start, end and speed regulation function. With this option function, it can be reliably and automatically connected with other equipment of the production line, such as screen, dust absorption, detection, conveying and barrel, etc., to complete the pressing production task of tablets synchronously. At the same time, different monitoring methods are used on the external equipment, providing high safety and reliability. The on-line detector can remove burr, flash and dust for the pressed tablet. Suction monitoring function is the use of flow monitor regularly in the suction pipe designated position of the suction pressure detection. The set value and the measured value are continuously compared. If the detector does not detect the inspiratory pressure (no flow) within 10s of the aspirating pipe, the tablet press will give a fault alarm and stop running. This function guarantees the reliability of production to the greatest extent and can continuously remove the dust in the process of tablet pressing production. The control technology connected with the whole tablet production line is a new technology of tablet production control and is the development trend in the future. The technology is still in its infancy at home.

Factory environment

Company in pharmaceutical machinery, pharmaceutical equipment, pharmaceutical equipment and other aspects of professional product development department. Our strong technical force, complete mechanical processing equipment, with advanced technology, tooling, testing, measurement, means and sound quality assurance system. The factory in the introduction, digestion and absorption of advanced foreign technology, on the basis of self development and manufacturing of various kinds of QVC type pneumatic vacuum feeder magnetic material ZP type rotary tablet press press machine, powder pelleting machine, machine, mixer, crusher, coating machine, screening machine, mute pressure suction machine agent granulator granulation machine hot air circulation oven number of spin vibration sieve machine sealing machine dressing machine, tablet press mould and so on, The products are suitable for pressing traditional Chinese medicine tablets, western medicine tablets, calcium tablets, oral lozenges, spirulina tablets, milk tablets, candy tablets, effervescent tablets, chewable tablets, flavoring blocks, mothballs, aromatic tablets, disinfection tablets, fertilizer tablets, pesticide tablets, button batteries, electronic components, metallurgical powder ceramic particles, etc.

![]()

![]()