High Speed Pharmaceutical Machinery / Rotating Dryer Medicine Processing/rotating dryer

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HUALIAN PHARMD |

| Certification: | ISO,GMP |

| Model Number: | FD-XSG |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard wooden case |

| Delivery Time: | 50 DAYS |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 80 |

|

Detail Information |

|||

| Model No: | FD-XSG | Voltage: | 220V/380V |

|---|---|---|---|

| Dimension(LxWxH):: | 1500x1090x1300 | Loading Capacity(L): | 1000 |

| Power(W): | 11kw | ||

| Highlight: | industrial vacuum dryer,fluidized bed granulator |

||

Product Description

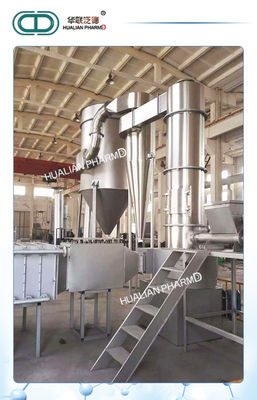

XSG Series High- Speed Rotating-Dryer

Flash evaporation dryer, the model successfully developed in 1970. At that time, jnorder to solve drying for the chemical industry high viscosity, paste materials, thecrystallization moisture of the product, mud and sludge cake. This model fordrying the above material plays on its unique performance. In subsequent decades, through scholars and enterprises constantly updated. It has reached aperfect level to design and manufacture at our company. We have the ability,confidence, interest in research and development flash dryer at the applicationand popularization of the various industries.

![]()

Principle:

Cold air is sent to the air heater through the air filtered by fan. The heated airentry to the bottom of drying tower as appropriate wind speed, and(installed inthe drying tower up)wet materials through spiral Feeder which produced a strongshear cutting, blowing floating, rotating, crush (external mechanical force)and SOon. This process will be that air transfer heat to wet material; Wet in material isgasified because of absorbing heat and separated with materials, taken away byair. The air is also reduced because the heat transferred. It used cyclone separationand high-voltage pulse bag filter to separate products and air, exhaust emissionsaway by the suction fan.

![]()

![]()

![]()

![]()

Application:

| Model | XSG-2 | XSG-4 | XSG-6 | XSG-8 | XSG-10 | XSG-12 | XSG-16 | XSG-20 |

| The host inside diameter(mm) | 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 | 2000 |

| Air volume(M3/h) | 350-500 | 1150-2000 | 2450-4500 | 4450-7550 | 7000-12500 | 10000-20000 | 18000-36000 | 28200-56500 |

| The evaporation of moisture(kg/h) | 12-17 | 40-70 | 80-150 | 150-250 | 230-4250 | 300-600 | 600-1000 | 1000-1500 |

| Maximum installed capacity(kw) | 10 | 20 | 40 | 65 | 85 | 105 | 150 | 230 |

| Maximum height(m) | 4.0 | 4.8 | 5.8 | 6.5 | 7.1 | 7.8 | 8.8 | 10.1 |

| Covers an area of(m2) | 15 | 20 | 28 | 35 | 40 | 52 | 80 | 150 |

Structural diagram:

![]()