Industrial Pharmaceutical Machinery / Round Or Square Dryer Vacuum Drying Ovens

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HUALIAN PHARMD |

| Certification: | ISO,GMP |

| Model Number: | FD-YZG/FZG |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard wooden case |

| Delivery Time: | 50 DAYS |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 80 sets/month |

|

Detail Information |

|||

| Model No: | FD-FZG | Quantity Of Baking Tray: | 20 Pcs |

|---|---|---|---|

| Layers Of Baking Support: | 5 | Weight Of Drying Chamber(kg)Kg): | 250 |

| Weight Of Drying Chamber(kg): | 1400 | Shape: | Round/square |

| Highlight: | film coating machine,fluidized bed granulator |

||

Product Description

FZG / YZG Model Vacuum Tray Dryer Vacuum Drying Oven

Principle:

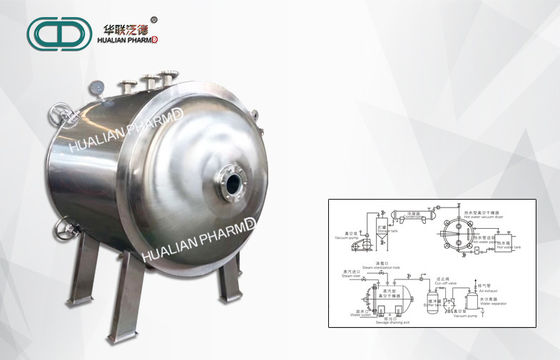

Note: if use condenser, the solvent in raw material can be recovered. If apply SKseries water ning vacuum pump, condenser might be canceled and the investmentand every could be saved.

![]()

Application:

It is suitable for drying heat sensitive raw materials that can decompose orpolymerize or deteriorate at high temperature, It is widely used in pharmaceutical,chemical, foodstuff and electronic industries.

![]()

![]()

![]()

![]()

![]()

Technical characters:

2.The heat source for evaporation may be low pressure steam or surplus heatsteam.

3.The heat loss is less.

4.Before drying. the treatment of disinfection may be crried out During theperiod of drying, there is no impurity material mixed. It is in conformity with therequirement of GMP.

5.It belongs to static dryer. So the shape of raw material to be dried should not bedestroyed.

Main Technical Parameter:

| Name/Model | YZG-600 |

YZG- 800

|

YZG-1000

|

YZG- 1400A

|

FZG-10

|

FZG-15

|

FZG-20 |

|

Inner size of drying chamber(mm) |

ф 600x 976 | ф 800x 1247 | ф 1000x 1527 | ф 1400x 2054 | 1500 x 1060 x 1220 | 1500x 1400x 1220 | 1500x 1800x 1220 |

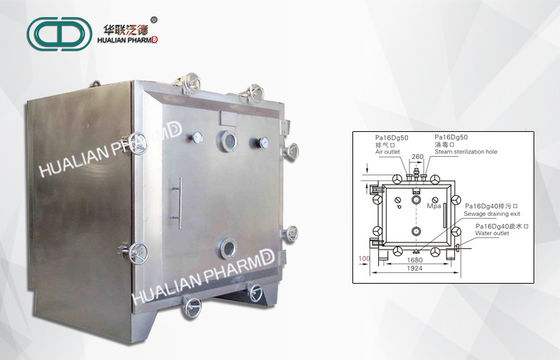

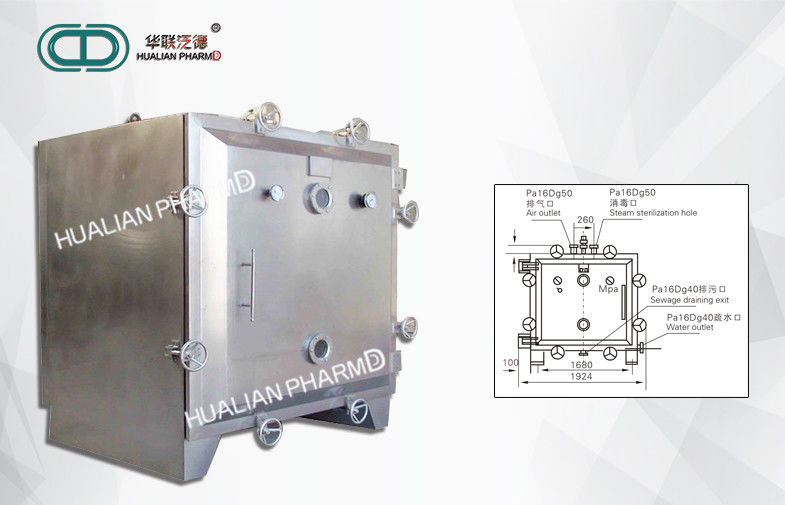

| Outer size of drying chamber(mm) | 1135 x 810x 1020 | 1700 x 1045 x1335 | 1693 x1190x1500 | 2380x 1675x 1920 | 1924x 1720x 1513 | 1924 X 2060x 1513 | 1924 x 2500x 1513 |

|

Layers of baking support |

4 | 4 | 6 | 8 | 5 | 8 | 12 |

| Interval(mm) | 81 | 82 | 102 | 102 | 122 | 122 | 122 |

| Size of baking tray(mm) | 310x 600x45 | 520x410x45 | 520x410x45 | 460x 640 x45 | 460x 640x45 | 460x 640x45 | 460x 640x45 |

| Quantity of baking tray | 4 | 8 | 12 | 32 | 20 | 32 | 48 |

| Working pressure inside the pipe ofbaking support( MPa) | <0.784 | <0.784 | <0.784 | <0.784 | <0.784 | <0.784 | <0.784 |

| Operation temperature ofbaking support(C) | 35~ 150 | 35~ 150 | 35~ 150 | 35~ 150 | 35~ 150 | 35~ 150 | 35~ 150 |

| Degree of vacuum inside the chamberwhen operation in idle (Mpa) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

|

Under the condition of- -0.1 Mpaand 110C, evaporation rate ofwate( kg/㎡·hr)

|

7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 |

| When condensor is used, Model,andpower of vacuum pump(kw) | 2X-15A2KW | 2X-30A3KW | 2X-30A3KW | 2X-70A5.5KW | 2X- 70A5.5KW | 2X- 70A5.5KW | 2X- -90A7.5KW |

| When condensor is not used, Model, .and power of vacuum pump(kw) | SK-0.51.5KW | SK-12.2KW | SK-12.2KW | SK-15.5KW | 2X- 70A5.5KW | SK25.5KW | SK2.5.5KW |

|

Weight of drying chamber(kg) |

250 | 600 | 800 | 1400 | 1400 |

2100 |

3200 |

Schematic of installation:

![]()