Automatic Liquid / Sauce Packing Machine For Ketchup , Tomato Sauce , Chili Sauce

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HUALIAN YIMIN |

| Certification: | ISO,GMP |

| Model Number: | HL-200JL |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | 50000 |

| Packaging Details: | standard wooden case |

| Delivery Time: | 70 DAYS |

|

Detail Information |

|||

| Model: | HL-200JL | Measuring Range: | 5-50g (depending On Material Characteristics)5-50g (depending On Material Characteristics) |

|---|---|---|---|

| The Bag Size: | L: 40-160mm, W: 15-48mm | Packing Speed: | 20-50 Packs/min (as Applicable) |

| Power: | 1.9 KW | Power Supply: | AC220V, 50/60Hz |

| Seal Type: | Pull-type Back Seal Filling Abnormal Angle | Net Weight: | 450kg |

| Machine Dimension: | L750 × W1100 × H1800mm | Tear: | Easy To Tear Side |

| Highlight: | sachet packaging equipment,pellet packaging machine |

||

Product Description

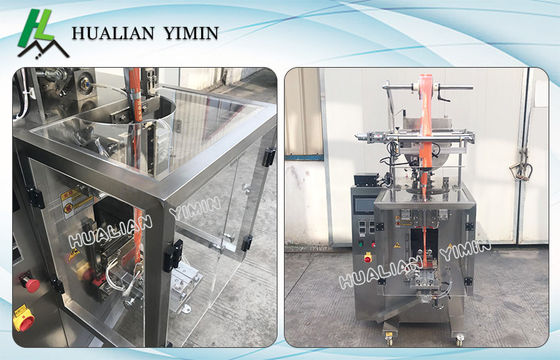

HL-200JL Automatic Liquid/ Sauce Packing Machine

Usage:

This machine is mainly used for the quantitative packaging of tomato sauce, hot pot sauce, salad sauce, edible oil, honey, yogurt, fruit juice, wine, vinegar, shampoo, hair conditioner, facial cream, medical and chemical liquid/sauce.

![]()

![]()

![]()

Function and features:

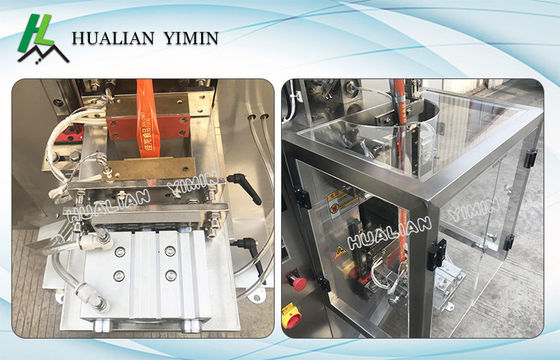

1. This machine can automatically complete following work: piston pump measuring--coding (optional)--bag making--filling--sealing-- hole punching (optional)--counting.

2.Computer/PLC control system, photoelectric tracking, maximizes the whole machine’s control precision, reliability and the intellectualized degree.

3.Has fault display system, easy to operate and maintenance.

4.Can choose mixing device, hopper heating device according to product character.

5.Machine body and all food touching part are made by stainless steel.

![]()

![]()

![]()

Technical parameters:

| Model |

HL-200JL |

| Measuring range | 5-50g (depending on material characteristics) |

| The bag size |

L: 40-160mm, W: 15-48mm |

| Packing speed | 20-50 packs/min (as applicable) |

| Power | 1.9 KW |

| Power supply | AC220V, 50/60Hz |

| Power | 1.6 KW |

| Seal type | Pull-type back seal filling abnormal Angle |

| Machine dimension | L750 × W1100 × H1800mm |

| Net weight | 450kg |

| Tear | Easy to tear side |

Process:

Code printing machine print production date → press longitudinal sealing knife seat → press and pull film driven up and down by transverse sealing broach seat → pump body quantitative punching material into the bag → press and pull film driven up and down by transverse sealing broach seat → cut transverse sealing edge holder and fill rounded corners with angular head abrasive tool (out of the finished product).

![]()

![]()

Brief description of the machine:

1,The appearance of the production equipment and material contact parts are 304 stainless steel, all machine structures are selected and designed in accordance with food hygiene standards;

2,All containers in contact with the materials are food grade SUS304 or food grade PP materials.

3,The structure which is often disassembled and cleaned adopts the connection of easy disassembling parts, so as to ensure the sanitation and convenience of handling when changing shifts or changing products.

![]()

![]()

Equipment accessories drawing:

![]()

If you want to know more about this product, please call our hotline to explain the packaging materials, packaging equipment (bag size, material, etc.), expected output, etc., so as to provide you with suitable models. If there are any other technical requirements, we will try our best to meet them. "Integrity is our promise, service is our quality" we sincerely look forward to happy cooperation with your company! Welcome to our company for investigation and negotiation.